新聞資訊

Address: Shenzhen City, Baoan District Xixiang Shu Donghua third industrial zone B building 7 floor

Telephone: 0755-2908-2001/2003

Fax: 0755-2908-2001

Q Q:540775041

Mailbox: 540775041@qq.com

URL: moieiieir.cn

Stamping process is the use of the principle of hot press transfer, anodized aluminum layer transfer to the substrate surface to form a metal special effect, because the main material used is aluminum foil stamping, therefore is also called stamping anodized hot stamping. Anodized aluminum foil is usually made of multilayer material. The substrate is often P E, followed by a separation coating, a color coating, a metal coating (aluminized) and a glue coating.

The printing industry is widely used in the aluminum foil stamping paper, called hot stamping, hot stamping is referred to as a process. Gilding does not mean "hot" is gold. Gilt paper material is divided into many kinds, including gold, silver, laser gold, laser silver, black, red, green and so on.

1. ordinary gold, laser gold stamping. For most products, including gold and silver stamping, laser card and glass on the card, the application of the more common.

2. positioning holographic gilding. Holographic laser positioning anodized aluminum design is a special process application, with the corresponding security patterns, can greatly improve the product security capabilities, but also improve the quality of products. This kind of anodized aluminum is usually made in China. Compared with imported foreign goods, the price is cheaper, but the gilding performance is a little worse. Holographic laser positioning anodized aluminum, hot stamping, bronzing pressure and speed control, and even bronzing models have a great relationship.

3. special applications of anodized aluminium in process. The first hot after printing is a new creative design and enlarging the printing industry. Application of the process requirements of anodized aluminum is very high, in addition to stamping position accurately, the surface smooth and shining, pressure balance, uniform, no foaming and paste version and other requirements, but also pay special attention to the edge of gilded pattern can not have obvious indentation, hot stamping anodized hot stamping surface with good adhesion, and no obvious scratch and scratch phenomenon. As you all know, the gilding process is actually a process of heating and compression of paper. The glass of white card, card, pay special attention to the protection of semi-finished products, in the production process to minimize the adverse factors of this paper deformation, stamping procedure smoothly, is of great help to improve the rate of qualified products.

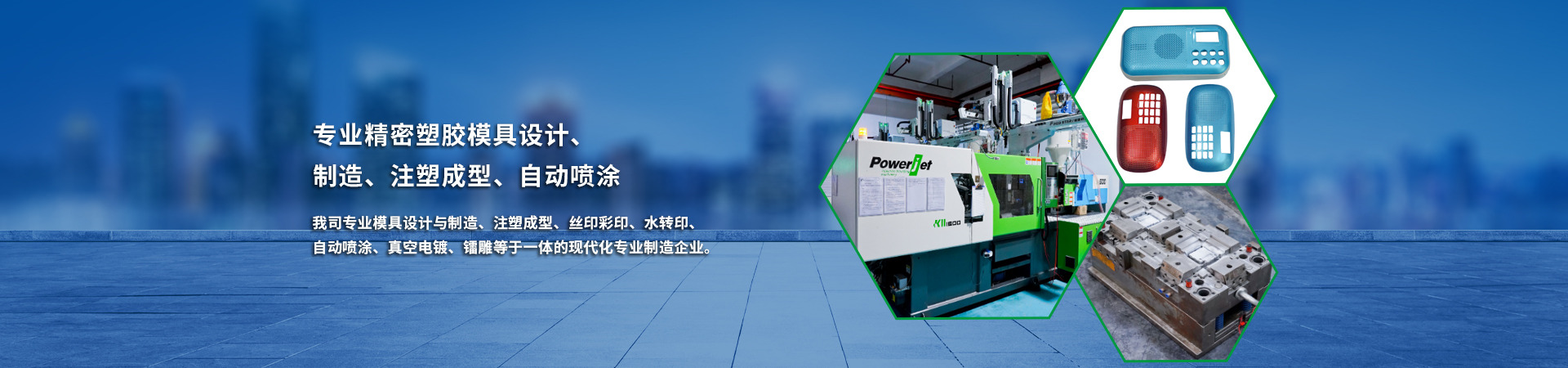

Shenzhen City Tengfei and plastic products Co., Ltd. was founded in 2008, is located in Shenzhen city of Baoan District Shu Donghua third industrial zone, professional mold design and manufacturing, injection molding processing, automatic painting. Vacuum plating, as well as various types of silk screen, UV silk screen, printing, water transfer, laser engraving, bronzing in one of the industrial companies.

Welcome customers both at home and abroad to visit our company and negotiate business. We look forward to working with you to create value! Telephone: 0755-2908-2001

755-2908-2001

755-2908-2001