新聞資訊

Address: Shenzhen City, Baoan District Xixiang Shu Donghua third industrial zone B building 7 floor

Telephone: 0755-2908-2001/2003

Fax: 0755-2908-2001

Q Q:540775041

Mailbox: 540775041@qq.com

URL: moieiieir.cn

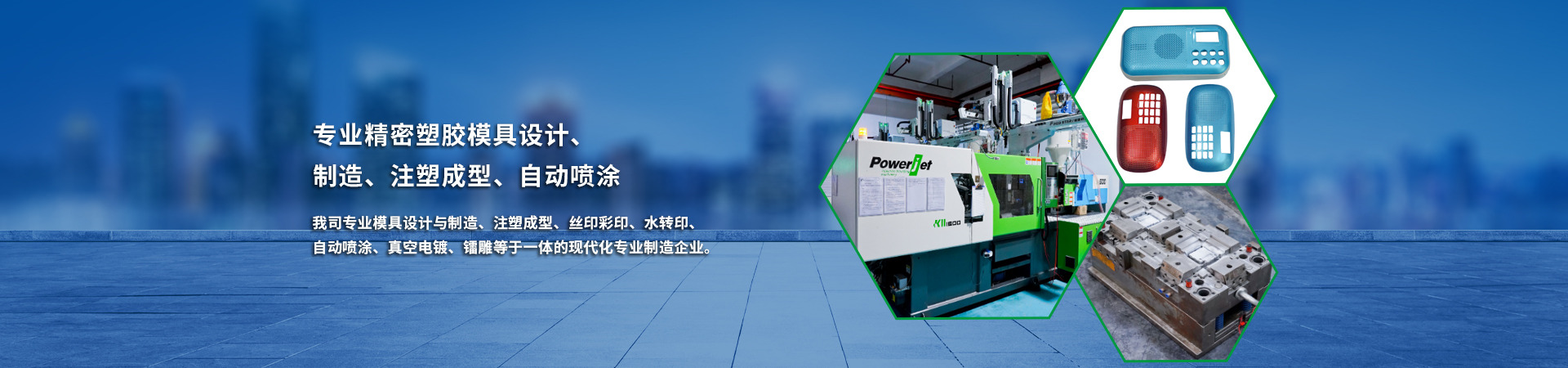

Plastic mold, for a combined plastic mold, injection molding, compression molding, extrusion blow molding and low foam molding, such as die with variable cavity composed of concave mould substrate, die components and die combination board, die with variable core is composed of a convex mold substrate, punch, punch card, component combination cavity blocking assembly and side cutting plate. The coordinated change of die, punch, die and auxiliary forming system. Can be processed in different shapes, different sizes of series of plastic parts.

The injection mold is a tool for the manufacture of plastic products and a tool for the complete construction and precise dimensions of plastic products. Injection molding is a processing method used in mass production of some complex shapes. Specifically, the melted plastic is injected into the mold cavity at high pressure by the injection molding machine, and then formed after cooling and solidification. The injection mould is composed of two parts, the moving die and the fixed mould. The moving die is installed on the moving template of the injection molding machine, and the fixed die is installed on the fixed template of the injection molding machine. In the injection molding, the moving die and the fixed die are closed to form a casting system and a mold cavity. When the mold is opened, the moving die and the fixed die are separated so as to remove the plastic product. In order to reduce the heavy workload of mould design and manufacture, the standard mould bases are mostly used in injection molding.

755-2908-2001

755-2908-2001