新聞資訊

Address: Shenzhen City, Baoan District Xixiang Shu Donghua third industrial zone B building 7 floor

Telephone: 0755-2908-2001/2003

Fax: 0755-2908-2001

Q Q:540775041

Mailbox: 540775041@qq.com

URL: moieiieir.cn

Shenzhen Tengfei plastic products Co., Ltd. injection mold maintenance professional knowledge

| 發(fā)布時間:2017-07-03 |

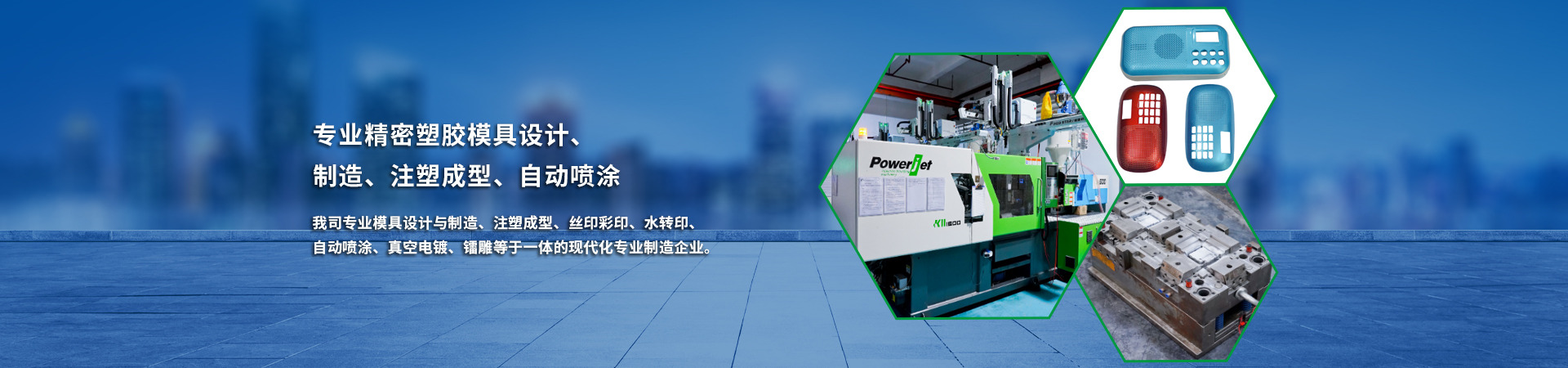

Shenzhen City Tengfei and plastic products Co., Ltd. was founded in 2008, is located in Shenzhen City, Baoan District Xixiang Shu Donghua third industrial zone, professional mold design and manufacturing, injection molding processing, automatic spraying, vacuum plating, and all kinds of screen printing, UV printing, printing, color printing, water transfer printing, laser engraving, bronzing in one of the industrial company. Tel: 0755-2908-2001 mail box: 540775041@qq.com website: moieiieir.cn

Here we introduce some details of the injection mold maintenance:

The first is to pay attention to the maintenance of the mold surface, also is the appearance of maintenance, can not let this die appearance damage, it is not allowed to corrosion, then choose a suitable, high-quality, professional anti rust oil is particularly important. When the mold to complete the production task, we should adopt different methods according to different injection molding carefully remove residual, available copper, copper wire and professional mold cleaning agent for injection mold and other residual sediments, and dry. Disable wire, steel bars and other hardware cleaning, so as not to scratch the surface. If there is corrosion caused by injection molding, rust point, use grinding machine grinding, polishing, and sprayed with professional anti rust oil, and then put the mold in a dry, cool, dust-free storage.

The second is to carry out regular cleaning of the injection mold, the mold is to ensure that health, on production, clean the mould to produce better products, and this is not to die by pollution.

Again is to mold parts detection, to see whether there is a fault die, ejector and a guide part role is to ensure that the mold opening and closing movement and top out of plastic parts, if any damage caused by parts and stuck, will lead to production, it should keep the mold lubrication thimble, guide pins (to choose the most suitable lubricant), and regularly check the thimble, guide pillars are deformed and surface damage, once discovered, should be promptly replaced; this avoids mold failure and affect production. Finally, enterprises should arrange for periodic injection of statistics, use, care and damage to the injection mold production, in order to timely find problems and minimize the impact on production.

Tengfei Huang is a professional injection molding manufacturer in Shenzhen. It is an injection molding process, automatic spraying and water transfer printing manufacturer. Welcome customers both at home and abroad to visit our company and negotiate business. We look forward to working with you to create value! Tel: 0755-2908-2001 moieiieir.cn

755-2908-2001

755-2908-2001